One of the first things that Mary and I set about doing upon our arrival in Cameroon was to interview people about their water use and sources and to do some water quality testing on those sources.

We bought the water testing kit back in Boston from an MIT professor. It mainly serves to identify whether or not a water sample contains E. coli or other coliform bacteria (coliform is defined “as gram-negative rods which produce acid and gas from lactose during metabolic fermentation”). Part of the sterile water sample is squirted onto a Petri-film on which E. coli will grow blue colonies and other coliform will grow red colonies. Another part of the sample is put in the Colilert tube. If E. coli are present then the sample will turn yellow and fluoresce under UV light. If just coliform are present the sample will still turn yellow but not fluoresce. The results of both the Petri-film and the Colilert tube are evaluated after 24 hours of incubation at body temperature.

We started with the water sources close to home at the ACREST Center. These include the nearby river, named the Mii, the rope pump outside the gate, and water from the rope pump that was then treated by a biosand filter manufactured by ACREST.

The River is used by many for washing and cleaning. Neighboring children come by the rope pump all the time to get water to carry home for cooking, washing, and drinking. The ACREST staff drinks the water from the biosand filter. Below is a picture of Colilert Test and Petrifilm Test results.

Water testing results.

The River is highly contaminated with E. coli and other coliform and is classified as high risk. The water from the well with the rope pump is not quite as dirty but is also classified as high risk because E. coli are present. But the water from the rope pump well treated by the biosand filter shows a dramatic difference. Coliform are present but the there was no E. coli found. The water is designated as low to intermediate risk. The biosand filter had improved the quality of the water and lowered its health risk.

The ACREST staff were trained by a Canadian NGO named Centre for Affordable Water and Sanitation Technology (cawst.org) in May 2008 to manufacture the biosand filter and since has manufactured many filters.

ACREST staff constructing a biosand filter.

A cross-section of the filter is shown below. They are constructed from concrete and other locally-available materials. The filtration is aided by the mechanical trapping by the sand, gravel, and stone and the natural ecology of the micro-organisms that grow in the filter. The filter works to remove parasites, bacteria, organic compounds, and some inorganic compounds to improve the quality of the water.

Taken from Biosand Filter Brochure made by CAWST (cawst.org).

ACREST has not fully begun marketing and disseminating their biosand filter, but we were able to visit the home where the first filter sold had been installed. The family treated all their drinking from their well with the filter and reported that it had improved the health of their family.

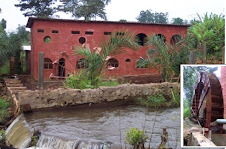

The first biosand filter bought from ACREST installed in a home near Bangang market.

Some maintenance and cleaning is required about every six months to keep the filter working properly. The top layer of sand needs to be cleaned and exchanged. Proper training on how to take care of the filter is given when the filter is purchased. On our visit to the compound, Simon showed the family how to maintain their filter.

Simon showing the family how to clean the sand in the filter.

A drawback of the filter is the amount of cement that it requires and the weight of the filter. Mary and I hope to help by slightly redesigning its structure in order to reduce its weight and cost.

LE FOYER AMELIORE EN ACTIVITE

LE FOYER AMELIORE EN ACTIVITE